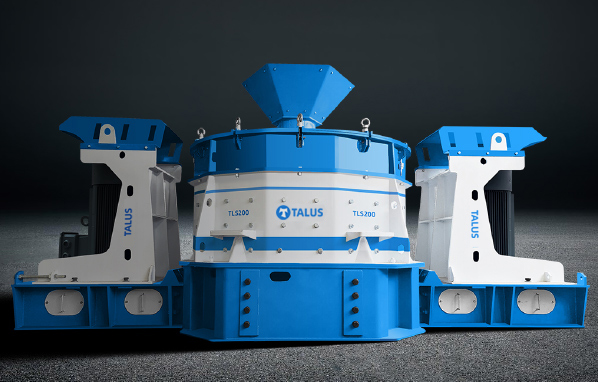

CH Series Single Cylinder Hydraulic Cone Crusher

High Pressure Resistance

High Crushing Ratio

Safety and Stability

Low Operation Energy Consumption

High Automatic and Intelligent Control

Good Granularity of Finished Product

Product Introduction

CH single cylinder hydraulic cone crusher is developed by introducing the product technology and design concepts of international famous mining machinery enterprises, optimizing and improving some technical details of the products locally, and realizing import substitution. The machine still adopts technical standards and assemblage process of European enterprises, and key components are imported from Europe or America. CH series cone crusher is widely used in medium and fine crushing operations of crushing systems in mines and engineering projects with its extraordinary process performance and mechanical performance.

Key Core Technologies

Many core technical backbones of our company have worked for 5 years in the crushing and screening division of the international renowned crusher manufacturing enterprise, mainly engaged in manufacturing, quality management and after-sales service management, with proficiency in a complete technical system and quality management in spare parts production, production and assembling, installation and commissioning, after-sales service etc.

Multi-layer dust-proof measures

Positive pressure dust control system keeps oil circuit clean durably.

Long-lasting production capacity

Constant crushing cavity type maintains a constant maximum feeding size and effective cavity cubage throughout entire lining wear period.

Adjustable multi-cavity type

Adaptability to multiple conditions. There are 7 cavity variations (EC-EF) to suit different operation conditions.

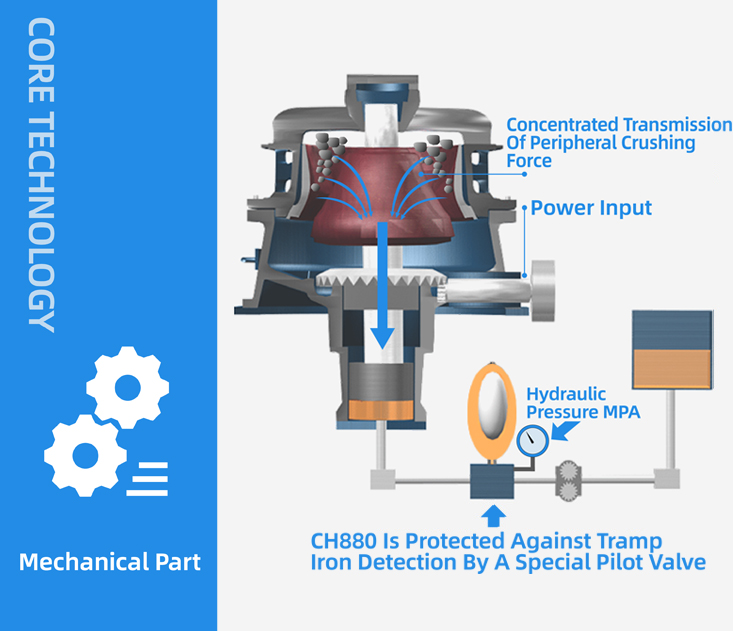

Hydraulic support design

Automatic control of cavity clearance; Intelligent adjustment of ore discharge port, tramp iron detection; Single cylinder hydraulic system, high crushing force.

Hydraulic oil is pumped from the hydraulic cylinder into the oil tank to lower movable cone to a suitable position

Hydraulic oil is pumped from the oil tank into the hydraulic cylinder to lift movable cone to a suitable position

Modular Box Design

Independent hydraulic control system, lubrication tank and oil pump control system. Safety interlock (temperature/flow) air-cooled oil cooler with automatic temperature control switch.

Multiple Automatic Control Functions

With multiple automatic control functions such as high-temperature protection, automatic tramp iron detection, overload protection, lubricant oil flow control, fault diagnosis, discharge opening calibration and wear diagnosis etc.

Key components are imported

Lubricating oil pump (Dior), hydraulic pump (Taiwan Yumeng), thermostat (Danfoss), pressure sensor (Danfoss), temperature sensor (Weika), Siemens touch screen, Siemens PLC, Schneider electronic components, and CMC soft starter.

Filtration system operates independently

Full-flow filter is connected in series between oil pump and main oil passages, thus filtering all lubricating oil entering the main oil passages.

Touch Screen Control System Interface

With assistance of position sensors and pressure sensors, the main axis position and discharge opening size can be automatically regulated by hydraulic cylinders to realize automatic control.

Advanced Control System

Easy to install and easy to operate with a touch screen interface; easy to modify data according to working conditions, easy to access stored historical operation data, event and alarm records.

Visual Intelligent Operation

Intelligent control and remote monitoring of the equipment can be achieved through cell phone APP, which can real-time monitor feeding quantity, current, oil temperature, mail axis temperature, vibration protection and other functions.

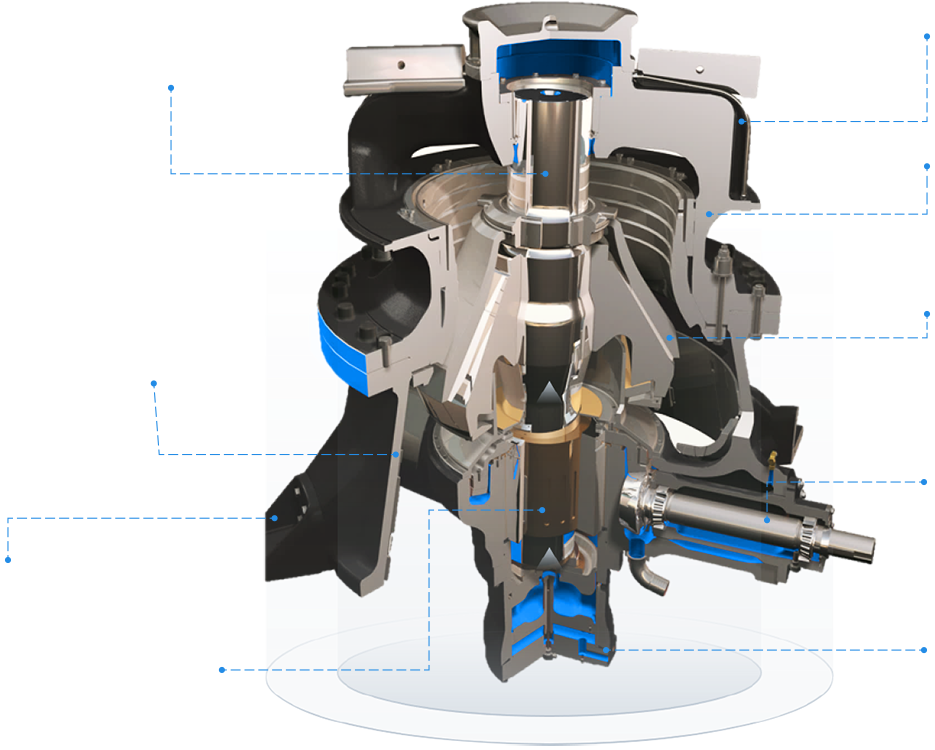

Product Structure

From exterior design to internal structure, every detail has been deliberately considered and tested.

Main axis

Top rack

Fixed cone liner

Movable cone liner

Bottom rack

Horizontal counter shaft

Spring rubber pad

Sector gear

Hydraulic cylinder

Main axis

Top rack

Fixed cone liner

Movable cone liner

Bottom rack

Horizontal counter shaft

Spring rubber pad

Sector gear

Hydraulic cylinder

CH series cumulative sieving throughput

Technical parameter

Multiple types available, there is always suitable one for you.

| Model | Power (kW) | Specification | Max. Feeding size (mm) | Nominal capacity in t/h with crusher running at CSS (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CH420 | 90 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||

| EC | 135 | 45-55 | 50-100 | 55-105 | 60-115 | 60-120 | 65-130 | 75-145 | |||||||

| C | 90 | 45-60 | 45-405 | 50-110 | 55-120 | 55-125 | 60-135 | 70-80 | |||||||

| M | 65 | 35-50 | 45-85 | 40-90 | 45-90 | 50-70 | |||||||||

| MF | 50 | 35-40 | 40-75 | 45-80 | 45-80 | 45-60 | |||||||||

| F | 38 | 30-60 | 30-60 | 30-65 | 35-55 | 40-45 | |||||||||

| EF | 28 | 30-40 with 80% finer than 4.5-5.5mm | |||||||||||||

| CH430 | 160 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||

| EC | 190 | 70-125 | 75-170 | 80-185 | 85-196 | 90-210 | 105-240 | 115-240 | |||||||

| C | 145 | 75-85 | 65-150 | 70-165 | 75-175 | 80-185 | 85-200 | 100-225 | 110-170 | ||||||

| MC | 115 | 55-65 | 60-160 | 65-175 | 70-785 | 75-200 | 80-210 | 96-165 | |||||||

| M | 90 | 60-75 | 65-100 | 70-150 | 75-165 | 80-175 | 85-185 | 90-175 | 105-120 | ||||||

| MF | 75 | 60-70 | 65-120 | 70-130 | 75-145 | 80-145 | 85-130 | 90-105 | |||||||

| F | 50 | 50-90 | 50-95 | 55-100 | 60-110 | 65-120 | 70-120 | 70-110 | 75-90 | ||||||

| EF | 35 | 70-90 with 80% finer than 5-5.6mm | |||||||||||||

| CH440 | 250 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||

| EC | 215 | 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 | |||||||

| C | 175 | 101 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 | ||||||

| MC | 140 | 97-122 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 | |||||||

| M | 110 | 117-187 | 126-278 | 136-298 | 145-318 | 154-339 | 176-281 | 194 | |||||||

| MF | 85 | 114 | 124-227 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 | |||||||

| F | 70 | 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 | ||||||

| EF | 38 | 100-125 with 80% finer than 6-7.5mm | |||||||||||||

| CH660 | 315 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||

| EC | 275 | 177 | 190-338 | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 | ||||||

| C | 215 | 171-190 | 184-367 | 196-480 | 209-501 | 238-582 | 263-643 | 288-512 | 317-353 | ||||||

| MC | 175 | 162-253 | 174-426 | 186-455 | 198-484 | 226-502 | 249-499 | 273-364 | |||||||

| M | 135 | 197-295 | 211-440 | 226-470 | 240-500 | 274-502 | 302-403 | ||||||||

| MF | 115 | 192 | 207-369 | 143-396 | 273-423 | 252-450 | 287-451 | 318-363 | |||||||

| F | 85 | 195-304 | 210-328 | 252-352 | 241-376 | 256-400 | 292-401 | 323 | |||||||

| EF | 65 | 211-293 | 227-316 | 244-298 | 161-290 | ||||||||||

| CH870 | 500 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||

| EC | 300 | 480-640 | 547-1277 | 605-1411 | 662-1546 | 730-1702 | |||||||||

| C | 240 | 540-772 | 616-1232 | 681-1362 | 746-1492 | 821-1643 | |||||||||

| MC | 195 | 541 | 576-864 | 657-1321 | 726-1361 | 795-1490 | 876-1642 | ||||||||

| M | 155 | 552-613 | 587-1043 | 669-1189 | 739-1314 | 810-1440 | 892-1586 | ||||||||

| MF | 100 | 514 | 549-933 | 584-993 | 666-1132 | 736-1251 | 806-1370 | 888-1420 | |||||||

| F | 90 | 531 | 570-832 | 609-888 | 648-945 | 739-985 | 816-885 | ||||||||

| EF | 80 | 364-420 | 395-532 | 426-574 | 458-616 | 489-658 | 520-700 | 593-798 | 655-882 | 718-883 | 790 | ||||

| CH880 | 600 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | ||

| EC | 460 | 480-640 | 547-1277 | 605-1411 | 662-1546 | 730-1702 | |||||||||

| C | 340 | 540-772 | 616-1232 | 681-1362 | 746-1492 | 821-1643 | |||||||||

| MC | 250 | 541 | 576-864 | 657-1321 | 726-1361 | 795-1490 | 876-1642 | ||||||||

| M | 180 | 552-613 | 587-1043 | 669-1189 | 739-1314 | 810-1440 | 892-1586 | ||||||||

| MF | 120 | 514 | 549-933 | 584-993 | 666-1132 | 736-1251 | 806-1370 | 888-1420 | |||||||

| F | 80 | 531 | 570-832 | 609-888 | 648-945 | 739-985 | 816-885 | ||||||||

| EF | 50 | 364-420 | 395-532 | 426-574 | 458-616 | 489-658 | 520-700 | 593-798 | 655-882 | 718-883 | 790 | ||||

Product show

From exterior design to internal structure, every detail has been deliberately considered and tested.

Difference of product quality

Difference between Talus product and other domestic product

Mechanical processing

Hardware component

Talus Single Cylinder Cone Crusher

Adopting European standard of strict quality testing and management system. All key components are imported to insure stability of material and machining precision.

Other Brand Single Cylinder Cone Crusher

Unable to comply with European standards of supply system in order to save cost. Unable to insure stability of material and machining precision.

Hydraulic oil station

Electric control part

All the key parts are imported and strictly comply with European standards, and the frame is made strictly according to European technology standards, which is more sturdy to meet severe heavy-duty conditions.

Unable to comply with European standards and domestic component is adopted in order to save cost, as well as lubrication oil pump, hydraulic oil pump, etc.

Automatic control

Intelligent part

Advanced intelligent PLC control system with powerful functions maximizes the capacity of the crusher.

Only being developed currently with insufficient manufacturing and after-sales experience.

More Device Recommendation

Perhaps you still need these devices recommended.

CLV Vertical Shaft Impact Sand Making Machine

PFL Vertical Compound Sand Making Machine

Talus Sand Making Machine

HP Multi Cylinder Hydraulic Cone Crusher

Please submit your request for a detailed product offer