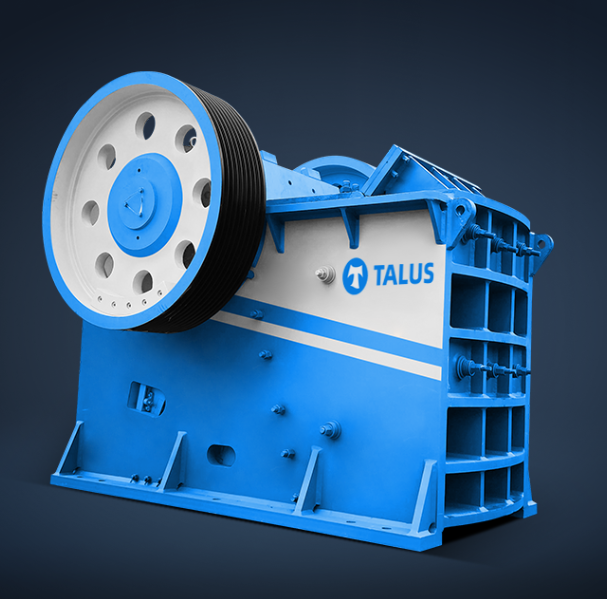

Jaw crusher, as the main equipment for ore crushing, is often called the "coarse crushing artifact". No matter how hard the stone, how big the block, are not a problem, and the operating efficiency is also very good. It is an optimal tool for crushing large rocks.

In fact, in addition to the coarse crusher, which is good at crushing large stones, there is also a fine crusher that is good at crushing small stones. This type of jaw crusher is called the "fine jaw crusher". So, besides this difference, what other differences are there between the coarse jaw crusher and the fine jaw crusher? Let's explore.

Introduction to the Coarse Jaw Crusher

The coarse jaw crusher is mainly used in the primary crushing position of the sand and gravel production line, specifically for the crushing of large stones. It is stable in operation, has a large crushing ratio, and has low operating costs. Therefore, this coarse jaw crusher can be seen in many sand and gravel crushing and sand making sites.

The coarse jaw crusher belongs to the PE series of jaw crushers, and commonly used models include PE200×300, PE200×350, PE250×400, PE400×600, PE500×750. Its production capacity can reach up to 1200 tons per hour.

Introduction to the Fine Jaw Crusher

The fine jaw crusher is mostly used in the secondary crushing of stone production lines. Due to its affordable price, many people use it instead of impact crushers or cone crushers.

The fine jaw crusher belongs to the PEX series of jaw crushers, and commonly used models include PEX150×750, PEX250×750, PEX250×1000, PEX250×1200, PEX300×1300. Its production capacity ranges from 8 to 105 tons per hour.

Differences between the Coarse Jaw Crusher and the Fine Jaw Crusher

1. Different feeding and discharge particle sizes

The feeding particle size of the fine jaw crusher is within 250mm, and the adjustable discharge particle size is between 18-90mm. The small discharge particle size, combined with the large crushing ratio, allows the crushed sand to be directly used in the construction industry. The feeding particle size of the coarse jaw crusher can reach up to 1mm, and the adjustable discharge particle size is between 1mm. A secondary crushing equipment needs to be configured behind it.

2. Different production capacities

The fine jaw crusher has fewer models, and due to the finer crushing particle size of the materials, it requires relatively longer crushing time, resulting in lower production capacity, with a range of approximately 8-105 tons per hour. The coarse jaw crusher has higher production efficiency, and there are also more models, with more than ten models available. Therefore, its production capacity is larger, and the production capacity of large models of coarse jaw crushers can reach up to 1 ton per hour.

3. Different applications

The fine jaw crusher is suitable for the secondary crushing stage, mainly for the fine crushing of materials after coarse crushing. It is widely used in industries such as metallurgy, mining, and cement. The coarse jaw crusher is generally used for primary crushing in the stone crushing production process, which is the first crushing operation.

In summary, both the coarse jaw crusher and the fine jaw crusher are early stone crushing equipment and can be considered the "big brother" in the mining machinery industry. After continuous development and improvement, many new series have emerged, with more targeted equipment that can better meet the production needs of different users, bringing immeasurable value to companies. They are indispensable helpers in the mining crushing industry!

If you want to learn more about sand-making and crushing equipment, you can consult our online customer service. At the same time, if you have any production line needs, we will arrange a professional project manager to provide you with detailed answers and configuration solutions.