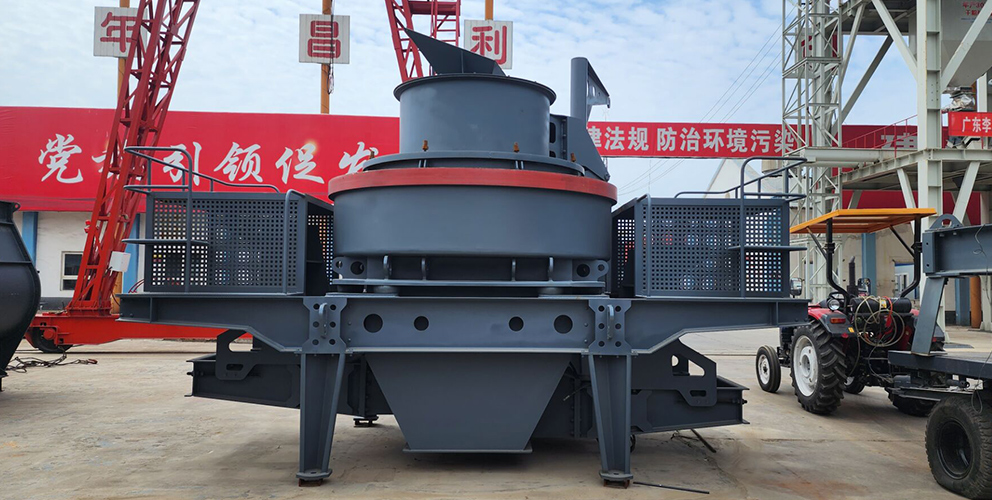

At present, the exploitation of sand making in China is very common, and a large number of sand making tools are used to rationalize the treatment of ore, so as to achieve a high utilization rate of sand. In the processing process, the widely used sand making equipment is still the impact crusher, also known as the impact sand making machine. This equipment has a very high production rate and produces uniform and high-quality products. Compared with other equipment, the working of this equipment is more outstanding. It adopts two crushing principles of "stone on stone" and "stone on iron", which makes the materials more fully processed and crushed.

Before the preparation work of the impact crusher, the equipment should be carefully inspected. After the equipment has no faults or safety hazards, sand making work can be carried out. First, let the crushed stone enter the equipment from the feed hopper. The material is divided into two parts by the distributor. One part enters the high-speed rotating impeller, which accelerates the material to several hundred times its acceleration. Then, it is ejected from the three evenly distributed flow channels of the impeller at a speed of about 65 meters per second. It then impacts the material lining in the vortex chamber together, rebounds from the material lining, and impacts the top of the vortex chamber obliquely, changing its direction of motion and deflecting downward. The material ejected from the impeller flow channel forms a continuous material curtain.

In this way, a piece of material is hit, rubbed, and crushed by each other two or more times in the whirling crushing cavity, and the crushed material is discharged from the lower discharge port. During the entire crushing process, the materials impact and crush each other on their own, without direct contact with metal components. Instead, they are crushed by impact and friction with the material lining, reducing corner contamination.

The impact crusher provides high-quality sand and gravel aggregates for various fields such as high-rise buildings, highway construction, large-scale water conservancy facilities, and concrete mixing plants, with higher profits. In addition, the impact crusher not only has a strong crushing capacity, but also saves 50% energy compared to traditional sand making machines, which has gained the trust and favor of customers both at home and abroad, and has achieved excellent market share in the national market.

Talus Equipment focuses on the field of mining crushing and screening, as well as sand-making equipment, providing cost-effective crushing and screening solutions, mechanism sand equipment, and high-grade sand and gravel aggregate for large-scale engineering projects such as highways, chemical industry, railways, hydropower, etc.

Welcome to visit and inspect Henan Talus, the manufacturer of crushing and sand making.