PE Series Jaw Crusher

High crushing ratio

High production efficiency

Safety and stability

Low energy consumption

Easy to operate and maintain

Good granularity of finished products

Product Introduction

Jaw crusher is an early crushing equipment, because of its simple structure, sturdy, reliable work, easy maintenance and overhaul, as well as relatively small production and construction costs, therefore, until now it is still widely used in metallurgy, chemical industry, building materials, electric power, transportation and other industrial sectors for crushing all kinds of ores and rocks with the compressive strength of 147 ~ 245MPa in the coarse, medium and fine crushing. In recent years, our company has specially developed the jaw crusher to meet requirements of crushing high-strength, high-hardness micro carbon ferrochrome in metallurgy, mining, construction and other industrial sectors.

Product Performance

Large crushing ratio and uniform granularity

① Optimized deep cavity crushing, with large stroke and steep bracket angle of toggle plate, and reasonable rotation speed, resulting in larger feeding size, higher output and more uniform granularity.

② Digital analysis of operation of each component, heavy-duty forged eccentric shafts, high manganese steel jaw plates and high cast steel movable jaw assemblies, the crushing ratio is as high as about 15, the production efficiency is greatly improved, and the capacity is 20-35% higher than that of ordinary jaw crushers with the same specifications.

② Digital analysis of operation of each component, heavy-duty forged eccentric shafts, high manganese steel jaw plates and high cast steel movable jaw assemblies, the crushing ratio is as high as about 15, the production efficiency is greatly improved, and the capacity is 20-35% higher than that of ordinary jaw crushers with the same specifications.

Compact structure, stable and reliable

① Adopting traditional basic design principle of compound pendulum. The structure is streamlined, easier to operate and maintain.

② Special centralized lubrication system, convenient replacement of component, lubrication more quickly, and minimal maintenance workload.

② Special centralized lubrication system, convenient replacement of component, lubrication more quickly, and minimal maintenance workload.

Longer service life and lower production cost , Reliable operation with multiple functions for one machine.

① The core parts are made of excellent high manganese steel castings, which are more recognized with longer service life, reducing the number of downtime for maintenance and lowering the production cost.

② Adopting hyperbolic jaw design to save wear and tear. Lifespan of jaw plate can be extended by more than 3-4 times under the same process conditions.

③ The perfect machining, heat treatment and flaw detection inspection of Talus Equipment Manufacturing makes the eccentric shaft have enough strength and rigidity, extending its service life.

② Adopting hyperbolic jaw design to save wear and tear. Lifespan of jaw plate can be extended by more than 3-4 times under the same process conditions.

③ The perfect machining, heat treatment and flaw detection inspection of Talus Equipment Manufacturing makes the eccentric shaft have enough strength and rigidity, extending its service life.

Multi-purpose and reliable operation

① Underboarding discharge adjustment device has a large range of discharge adjustment, reliable operation and flexible usage, which can meet various processing requirements of customers.

② Low operating noise and dust-proof equipment can be optional equipped, in line with national environmental standards.

② Low operating noise and dust-proof equipment can be optional equipped, in line with national environmental standards.

Operation Principle

Working mode of PE series of crushers is driven extrusion. The operation principle is as follows. Electric motor drives belt and pulley, and then drives eccentric shaft to swing movable jaw up and down. When movable jaw raises, angle between toggle plate and movable jaw increases, then pushes movable jaw plate closer to fixed jaw plate. At the same time, the material is crushed or chopped. When moving jaw descends, angle between toggle plate and moving jaw decreases, moving jaw plate leaves fixed jaw plate away under the action of spring and tension rod. Meanwhile chopped material is discharged from hopper outlet of crushing cavity. With the continuous rotation of electric motor, movable jaw crushes and discharges materials periodically to achieve mass production.

Technical parameter

Multiple types available, there is always a suitable one for you.

| Model | Feeding size(mm) | Max. feeding size(mm) | Adjustable discharge range(mm) | Capacity(t/h) | Eccentric shaft rotation(r/min) | Power(kW) | Overall dimensions(L×W×H)(mm) |

|---|---|---|---|---|---|---|---|

| PE-1600×2100 | 1600×2100 | 1500 | 300-400 | 1300-2200 | 160 | 380 | 6210×4013×4716 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 280 | 5160×3660×4248 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 220 | 4200×3300×3500 |

| PE-1000×1200 | 1000×1200 | 850 | 195-300 | 280-560 | 200 | 160 | 3480×2876×3330 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 200 | 132 | 3380×2870×3330 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 110 | 2660×2430×2800 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-180 | 250 | 75 | 2190×2206×2300 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 55 | 1980×2080×1870 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 1730×1730×1630 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 1300×1090×1270 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 11 | 1000×870×990 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 910×750×990 |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 720×660×850 |

Product Structure

From exterior design to internal structure, every detail has been deliberately considered and tested.

Lining Plate of Movable Jaw

Upper Lining Plate

Movable Jaw

Fixed Jaw Plate

Adjustment Device

Movable Jaw Plate

Spring

Lower Lining Plate

Toggle Plate

Frame

Gasket of Toggle Plate

Tension Rod of Movable Jaw

Lining Plate of Movable Jaw

Upper Lining Plate

Movable Jaw

Fixed Jaw Plate

Adjustment Device

Movable Jaw Plate

Spring

Lower Lining Plate

Toggle Plate

Frame

Gasket of Toggle Plate

Tension Rod of Movable Jaw

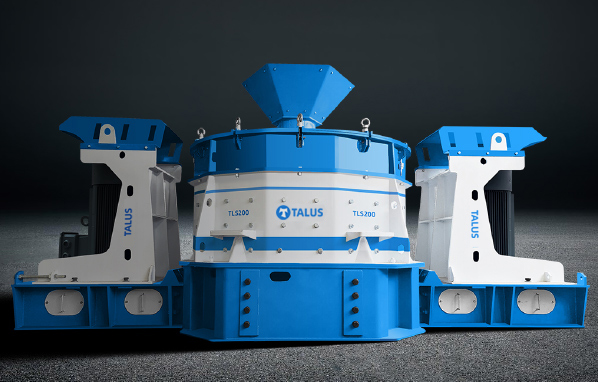

Product Show

From exterior design to internal structure, every detail has been deliberately considered and tested.

More Device Recommendation

Perhaps you still need these devices recommended

CLV Vertical Shaft Impact Sand Making Machine

PFL Vertical Compound Sand Making Machine

Talus Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

Please submit your request for a detailed product offer