PF Series Impact Crusher

Large Crushing Ratio

High Productivity

Security and Stability

High Comprehensive Benefit

Easy to Operate and Maintain

Good Granularity of Finished Product

Product Introduction

PF series impact crusher is a new type of crushing equipment developed and designed by Talus Equipment Manufacturing by summarizing feedback from customer’s actual use and years of production experience. It adopts new manufacturing process and special structural design, and the finished product is cubic with good granularity, without tension and cracks, capable of crushing all kinds of coarse, medium, and fine materials (granite, limestone and concrete etc.) whose feeding particle size not exceeding 300-700mm and whose compressive strength not more than 350MPa, and the discharge size can be adjusted to diversify the crushing specification.

Product Performance

Large Crushing Ratio and Uniform Granularity

High Productivity!

① Generous feeding opening, deep crushing cavity and a heavy-duty rotor is adopted and finite element force analysis is carried out, the rotational inertia is larger, so that the equipment has a larger crushing ratio and the crushing capacity is improved.

② Clearance between impact plate and hammer bar can be adjusted flexibly. By designing grinding cavity, the discharge particle size can be controlled, and the granularity is good, and content of stone powder is low.

② Clearance between impact plate and hammer bar can be adjusted flexibly. By designing grinding cavity, the discharge particle size can be controlled, and the granularity is good, and content of stone powder is low.

Simple Body Structure - Stable and Reliable

Shorten payback period!

① Strong product universality. Double cavity crusher can be changed into triple cavity crusher by adding a grinding rack without replacing other parts, which reduces user’s secondary investment.

② Standardized design of liner has strong interchangeability, reducing variety and inventory of spare parts, thus reducing customer investment.

② Standardized design of liner has strong interchangeability, reducing variety and inventory of spare parts, thus reducing customer investment.

Longer Service Life - Reduce Production Costs

Hydraulic lid opening and easy replacement.

① The utility parts are made of high chromium material and composite casting utility materials. It has good impact resistance and utility performance after rigid thermal treatment, thus prolonging the service life of equipment and utility parts.

② Impact crusher is equipped with the same two hydraulic flap devices on both sides of the rack. It is easy for users to open rack and replace the parts. The hammer bar locking device makes replacement of hammer bar more simple, convenient and quick.

② Impact crusher is equipped with the same two hydraulic flap devices on both sides of the rack. It is easy for users to open rack and replace the parts. The hammer bar locking device makes replacement of hammer bar more simple, convenient and quick.

Outstanding Machining and Assembly Technology

Overload and tramp iron protection devices make equipment operate more smoothly.

① Before assemble of rotor, static and dynamic balance test should be conducted. The main axis adopts excellent forging parts for machining, and adopts expansion sleeve tightening connection method, which makes the equipment run more reliably.

② Optimized overload and tramp iron protection devices. When impact crusher exceeds its safe load, clearance between impact plate and discharge opening will be regulated in time to prevent equipment shutdown caused by overload.

② Optimized overload and tramp iron protection devices. When impact crusher exceeds its safe load, clearance between impact plate and discharge opening will be regulated in time to prevent equipment shutdown caused by overload.

Operation Principle

Impact crusher is a kind of crushing machine which utilizes impact energy to break materials. When the machine works, driven by the electric motor, the rotor rotates at high speed, the material enters action area of hammer bar, crushes with the hammer bar on the rotor, and then it is thrown to impact device to be crushed again, and then bounces back to the hammer bar reaction area to be crushed again from the impact liner. This process repeats itself, and the material enters primary, secondary and tertiary impact cavities from large to small for repeated crushing, until the material is crushed to the required granularity and then discharges from discharge opening. Clearance between the impact rack and the rotor can be adjusted to change material discharge granularity and shape of the material.

Technical Parameter

Multiple types available, there is always suitable one for you.

| Model | Rotor diameter (mm) | Feeding opening size (mm) | Max. Feeding side length (mm) | Capacity (t/h) | Motor Power (kW) | Overall Dimension(L×W×H) (mm) |

|---|---|---|---|---|---|---|

| PF-1820 | Φ1800×2000 | 1620×2040 | 800 | 550-800 | 630-710 | 4471×3250×4008 |

| PF-1620 | Φ1612×2000 | 1315×2040 | 700 | 400-600 | 500 | 4236×3572×3735 |

| PF-1520 | Φ1512×2000 | 1315×2040 | 700 | 350-450 | 400-450 | 4138×3422×3649 |

| PF-1320 | Φ1320×2000 | 900×2030 | 500 | 160-350 | 260-300 | 3320×3218×2613 |

| PF-1318 | Φ1320×1500 | 880×2000 | 350 | 150-260 | 220-260 | 3100×3210×2613 |

| PF-1315 | Φ1320×1500 | 860×1520 | 350 | 120-250 | 180-220 | 3100×2800×3160 |

| PF-1214 | Φ1250×1400 | 400×1430 | 300 | 90-180 | 132-160 | 2850×2400×2900 |

| PF-1210 | Φ1250×1050 | 400×1080 | 300 | 70-130 | 110-132 | 2800×2150×2900 |

| PF-1010 | Φ1035×1050 | 400×1080 | 300 | 50-90 | 55-75 | 2650×2150×2900 |

| PF-1007 | Φ1000×700 | 400×730 | 250 | 15-60 | 37-55 | 2440×1580×2672 |

Product Structure

From exterior design to internal structure, every detail has been deliberately considered and tested.

Tension Rod

Front Impact Rack

Rear Impact Rack

Hammer Bar

Impact Liner

Rotor Rack

Main Axis

Locking Blocks

Compression Plate

Tension Rod

Front Impact Rack

Rear Impact Rack

Hammer Bar

Impact Liner

Rotor Rack

Main Axis

Locking Blocks

Compression Plate

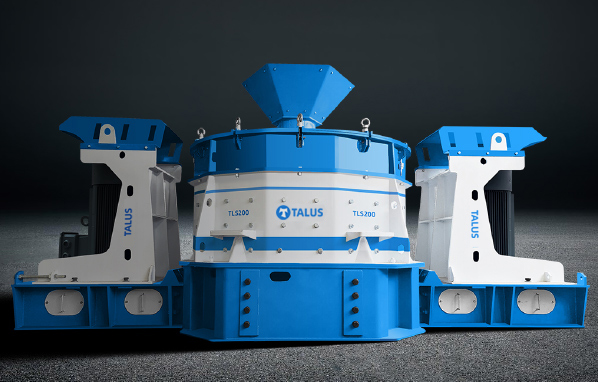

Product Show

From exterior design to internal structure, every detail has been deliberately considered and tested.

More Device Recommendation

Perhaps you still need these devices recommended

CLV Vertical Shaft Impact Sand Making Machine

PFL Vertical Compound Sand Making Machine

Talus Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

Please submit your request for a detailed product offer