PFL Vertical Compound Sand Making Machine

High throughput

High crushing ratio

High sand making efficiency

Good granularity of finished product

Low energy consumption

Safety and stability

Equipment Introduction

Compound sand maker (compound sand crusher) is a new product optimized and designed by our company combined with domestic and foreign fine crushing technology, which has significant performance advantage and is used for crushing and processing hard materials such as shale, glass, ceramics, bluestone, metal ore, etc., with a compressive strength of less than 140 MPa and a humidity of no more than 15%. It is widely used in mining, metallurgy, wear-resistant materials, cement, coal, glass, ceramics, and electric power and other industries.

The main features are:

① Large crushing ratio. High production, 1.4 times higher than similar domestic products.

② Energy saving.

③ The wearing parts are made of high hardness, high toughness, and multi-alloy materials, which improves the service life by 2-3 times.

④ The clearance between hammer and impact plate is adjustable, which can meet requirements of various fineness.

Performance Advantage

High wear resistance and easy adjustment of wearing parts

PFL series compound sand maker has a larger feeding size up to 240 mm, a finished discharge size of <3mm, and a large crushing ratio. The primary yield is as high as 70% - 90%.

Vertical crushing cavity with high throughput

There is no partition or grate in the middle of vertical crushing cavity, which makes feeding process smoothly. The crushing process is vertical, which has a high throughput and a fast passing rate, resulting in a high production and relatively lower energy consumption.

Unique throwing feeder tray structure reduces the cost of use

Hammer and reaction liner are distributed in a cross pattern around the circumference in the feed tray. When the hammer is worn out, it can be used as reaction liner, which improves the material utilization rate and reduces the cost of use.

Specially designed water-cooled structure and high-temperature materials can be crushed.

High-temperature materials below 150°C can be crushed. High-temperature bearings can withstand high-temperature lubricating grease above 260 °C.

High efficiency, energy-saving and smooth operation

The equipment has two structural forms of upper transmission and lower transmission, which is highly efficient and energy-saving. When matched with the mill, it can increase the output of the mill by about 40% and reduce the power consumption of the system by about 30%. The equipment runs smoothly, with low noise, low vibration and good sealing. Convenient operation, small footprint, easy installation and maintenance.

Special rotor structure for higher equipment performance

The optimized design of equipment rotor forms a multi-stage continuous crushing cavity, which makes full use of energy and space and improves the performance of the machine.

The chassis is equipped with protective plates, which can crush materials with high hardness and abrasion.

For materials with high hardness and abrasion (quartz stone, silica, river pebbles, and highly abrasive dolomite), the chassis can be optionally fitted with protective plates to avoid abrasion of the chassis body.

Product Structure

From exterior design to internal structure, every detail has been deliberately considered and tested.

Pulley

Feeding hopper

Cover

Motor

Main axis

Upper motor

Lower motor

Cylinder

Discharge hopper

Pulley

Feeding hopper

Cover

Motor

Main axis

Upper motor

Lower motor

Cylinder

Discharge hopper

Performance Parameter

Multiple types available, there is always suitable one for you.

| Model | Feeding size(mm) | Discharging size(mm) | Main axis rotation(r/min) | Capacity (t/h) | Power (kW) | Overall dimension(L×W×H)(mm) |

|---|---|---|---|---|---|---|

| PFL-750lll | <100 | <3 | 800~1350 | 8~20 | 45 | 2370×1150×1300 |

| PFL-1000lll | <120 | <3 | 650~980 | 15~30 | 55 | 2600×1420×1520 |

| PFL-1250lll | <150 | <3 | 510~770 | 35~45 | 90 | 3070×1690×1660 |

| PFL-1500lll | <180 | <3 | 430~640 | 50~70 | 132 | 3390×2050×2030 |

| PFL-1750lll | <200 | <3 | 420~540 | 70~100 | 160 | 3820×2360×2080 |

| PFL-2000lll | <220 | <3 | 360~500 | 90~20 | 200 | 4080×2610×2180 |

| PFL-2300lll | <240 | <3 | 330~450 | 120~160 | 250 | 4472×2930×2554 |

More Device Recommendation

Perhaps you still need to learn more about devices recommended.

CLV Vertical Shaft Impact Sand Making Machine

CH Single Cylinder Hydraulic Cone Crusher

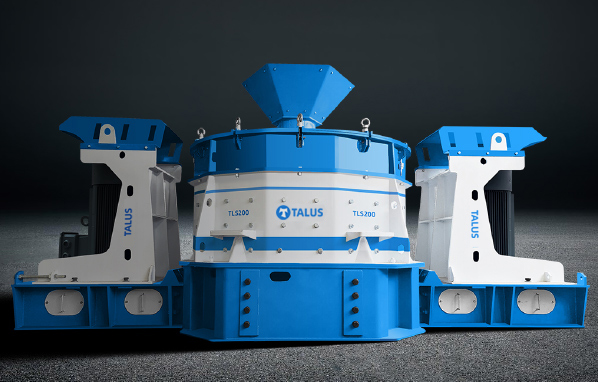

Talus Sand Making Machine

HP Multi Cylinder Hydraulic Cone Crusher

Please submit your request for a detailed product offer