Granite is hard and has strong resistance to corrosion and wear. It also has a large storage capacity of raw materials, making it an ideal choice for stone sand-making materials. After being processed by professional equipment,it can be used as high-quality sand and stone aggregate in various construction industries. So, what equipment is needed for granite sand production?

The prospects of granite sand production are promising and profitable:

1. Currently, there is a high demand for sand and stone aggregates in China, and natural sand resources are scarce and unable to meet the demand. Mechanism sand has abundant and cheap raw material resources, so the production of sand from stones has gradually gained attention.

2. Granite has excellent texture, compact structure, high compressive strength, strong durability, and good stability. It has inherent advantages. Combined with high-quality sand production, it can generate substantial profits. Therefore, granite is usually the preferred choice for sand production.

Equipment for granite sand production

The process of granite sand production generally includes crushing, screening, sand making, and sand washing, which requires the use of coarse crushing equipment, medium and fine crushing equipment, screening equipment, sand making equipment, conveying equipment, and sand washing equipment. For granite sand production, we recommend the "jaw crusher + cone crusher" configuration based on the characteristics of granite.

A complete granite sand production line includes feeding, coarse crushing, fine crushing, sand making, sand washing, screening, conveying, etc. Different customers have different scales for their granite sand production plants, so the equipment configuration may vary.

1. Coarse crushing: Jaw crusher, mobile jaw crusher. Responsible for coarse crushing of raw granite stones, reducing large stones into smaller sizes with a higher crushing ratio.

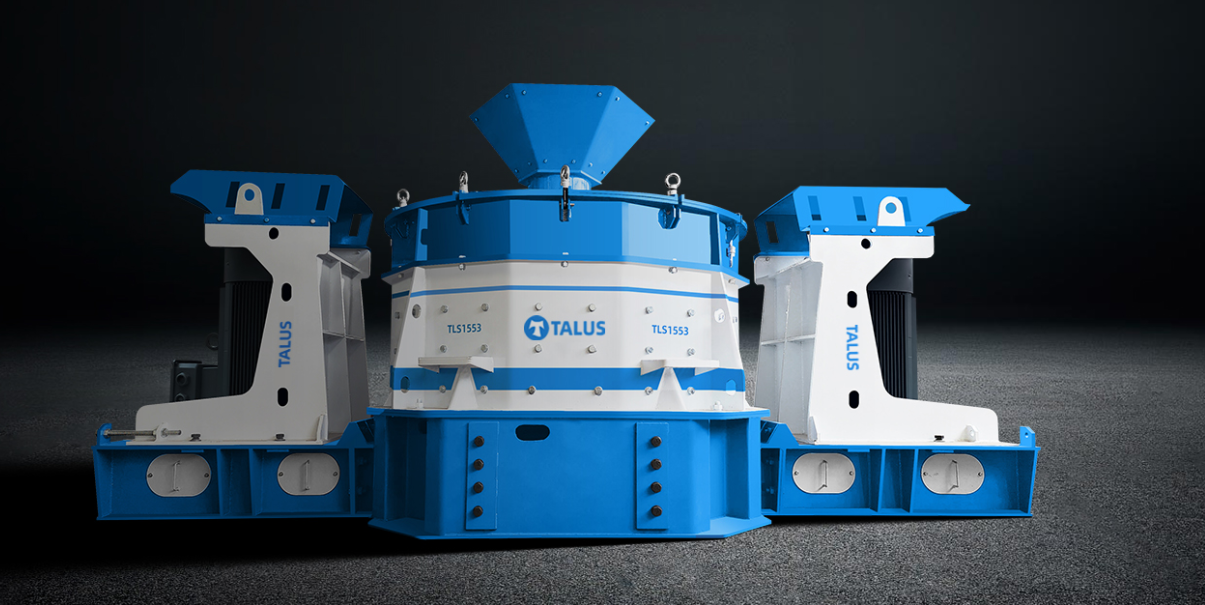

2. Fine crushing: Impact crusher, cone crusher. Impact crushers produce well-shaped finished products, while cone crushers have higher crushing capacity.

3. Sand making: Sand maker, mobile sand maker. Produces finished sand that meets customer requirements and can adjust the size and type of sand.

4. Sand washing: Sand washer. Cleans impurities in the sand and ensures the purity of the finished sand.

In addition, some auxiliary equipment needs to be configured, such as vibrating feeder, vibrating screen, belt conveyor, etc.

Our company has provided complete sets of granite sand production equipment for many customers, with excellent processing effects, various types of output, and can meet the demand for construction sand.

If you want to learn more about crushing and sand making equipment, you can consult our online customer service. If you have any requirements for production lines, we will arrange a professional project manager to provide detailed answers and equipment configuration.