The rapid development of railway construction has brought more convenience to people's lives, which is closely related to the role of ballast. The so-called railway ballast refers to the crushed stone used for laying roads and railway subgrades. These crushed stones are made of granite and marble. They can reduce vibration and play a significant role when trains pass by, so these crushed stones are required to have high quality. The use of cone crusher is indispensable in the process of crushing these materials.

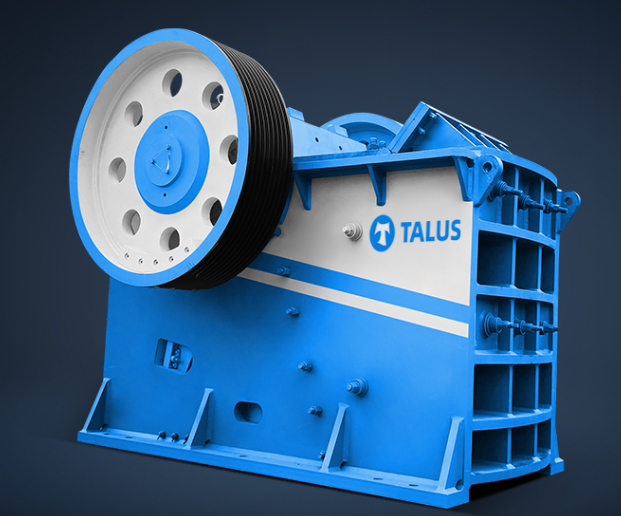

The cone crusher is a medium and fine crushing equipment that plays an important role in material production. With the continuous development of the times, its structure and technological content are constantly improving and enhancing. Therefore, its performance is constantly improving, bringing better advantages in material production. Here, we analyze the advantages and problems that it may bring in crushing railway ballast.

Advantage 1: Better crushing effect

The cavity type of the cone crusher is optimized and designed, and it adopts the working principle of laminated crushing. This makes the quality of the crushed product better, more solid, and greatly reduces the phenomenon of over crushing. The product gradation is reasonable, making it the preferred choice for railway ballast production.

Advantage 2: Higher Production Capacity

The cone crusher has mature and exquisite technology, which achieves good coordination of the crushing cavity shape and operating parameters. This allows it to have higher production efficiency in the crushing of railway ballast. The machine can also meet different capacity requirements by converting the crushing cavity type, thus achieving the function of multi-purpose use.

Advantage 3: Environmental Friendly

This is a concept that has emerged in recent years to improve people's living standards. The environmental performance of the cone crusher is mainly reflected in its low ash leakage and reduced dust pollution. The equipment is equipped with dust collectors and silencers, which makes the production process more environmentally friendly.

Advantage 4: More convenient operation

This is because the cone crusher has multiple crushing cavity types, flexible eccentric distance, and a high degree of automation. It is easier to operate and more time-saving and labor-saving. The equipment can be remotely monitored for its operation, which greatly liberates labor.

The above mainly introduces the advantages of cone crushers in railway ballast crushing, including large production capacity, good crushing effect, convenient operation, and environmental friendliness.

If you want to learn more about crushing and sand making equipment, you can consult our online customer service. If you have any requirements for production lines, we will arrange a professional project manager to provide detailed answers and equipment configuration.